Discover the Advantages of Modern Control Panels

- Ryan Patrick Murray

- Dec 8, 2025

- 4 min read

In today’s fast-paced industrial and marine environments, efficiency and reliability are non-negotiable. Modern control panels have transformed the way we manage electrical systems, offering unprecedented control, safety, and adaptability. As someone deeply involved in the design and implementation of electrical systems, I’ve witnessed firsthand how these advancements can redefine operational success. Let’s explore the tangible benefits that modern control panels bring to the table.

Why Modern Control Panels Matter

Modern control panels are not just upgraded versions of their predecessors. They represent a leap forward in technology, design, and functionality. These panels integrate advanced components such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and smart sensors. This integration allows for real-time monitoring, precise control, and seamless communication between different system parts.

The advantages are clear:

Enhanced Safety: Modern panels include built-in diagnostics and fault detection, reducing the risk of electrical hazards.

Improved Efficiency: Automation and remote control capabilities minimize downtime and optimize energy use.

Scalability: Modular designs allow easy expansion or modification as operational needs evolve.

User-Friendly Interfaces: Intuitive displays and controls reduce training time and operator errors.

These features are crucial in environments where downtime can cost thousands and safety is paramount.

Key Features of Modern Control Panels

Understanding the core features of modern control panels helps clarify why they outperform traditional setups. Here are some of the most impactful elements:

Programmable Logic Controllers (PLCs)

PLCs serve as the brain of the control panel. They execute complex control algorithms, manage inputs and outputs, and communicate with other devices. Their programmability means they can be tailored to specific applications, from simple motor control to complex process automation.

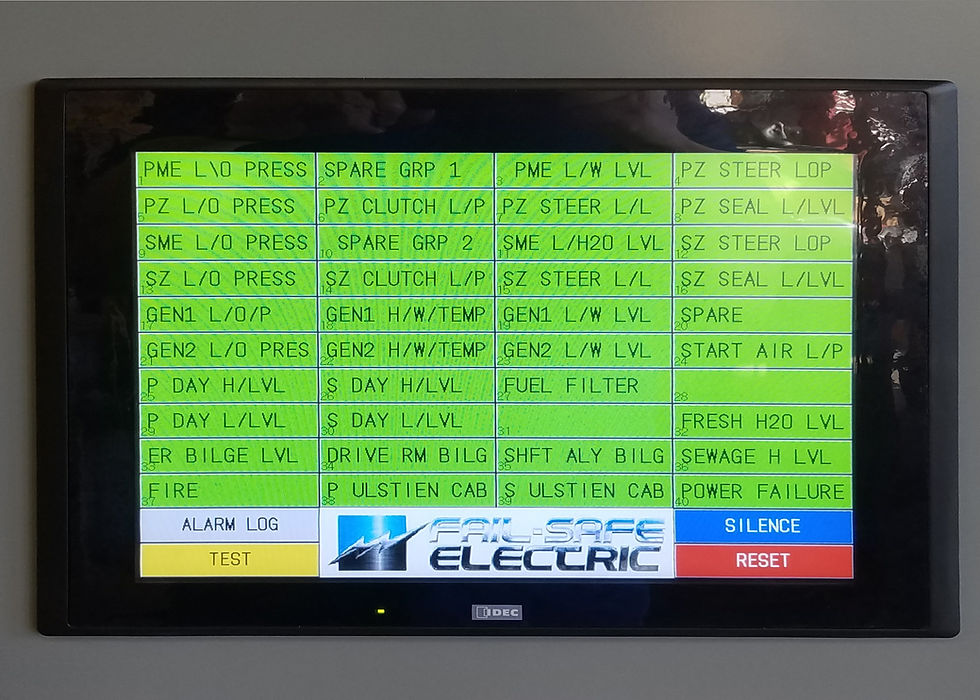

Human-Machine Interfaces (HMIs)

HMIs provide operators with a clear, graphical view of system status. Touchscreens and customizable displays make it easy to monitor performance, adjust settings, and respond to alarms quickly.

Smart Sensors and Actuators

These components provide accurate data on temperature, pressure, flow, and other critical parameters. Their integration allows for predictive maintenance and reduces unexpected failures.

Communication Protocols

Modern panels support multiple communication standards such as Ethernet/IP, Modbus, and Profibus. This interoperability ensures smooth integration with existing systems and future upgrades.

Safety and Compliance Features

Built-in circuit protection, emergency stop functions, and compliance with industry standards ensure that the panels meet stringent safety requirements.

These features combine to create a control system that is not only powerful but also adaptable and secure.

What is the control panel?

At its core, a control panel is an assembly of electrical components designed to manage and regulate machinery or processes. It acts as the central hub where power distribution, control logic, and user interfaces converge. Traditionally, control panels consisted of simple switches, relays, and circuit breakers. Today, they have evolved into sophisticated systems incorporating digital technology and automation.

The primary purpose of a control panel is to:

Distribute electrical power safely and efficiently

Control machinery operation through automated or manual inputs

Monitor system performance and provide feedback

Protect equipment and personnel from electrical faults

In industrial and marine settings, control panels are critical for ensuring smooth operations, minimizing downtime, and maintaining safety standards. Their design must consider environmental factors such as vibration, moisture, and temperature extremes, especially in marine applications.

Practical Benefits in Industrial and Marine Applications

The advantages of modern control panels become even more apparent when applied to real-world scenarios. Here’s how they make a difference:

Reduced Downtime

With real-time diagnostics and remote monitoring, operators can identify and address issues before they escalate. This proactive approach minimizes unplanned outages.

Energy Savings

Intelligent control algorithms optimize motor speeds, lighting, and HVAC systems, reducing energy consumption without compromising performance.

Simplified Maintenance

Modular components and clear labeling make troubleshooting and repairs faster and less error-prone. Predictive maintenance alerts help schedule service before failures occur.

Enhanced Safety

Automated shutdowns and emergency stop functions protect personnel and equipment. Compliance with safety standards reduces liability and insurance costs.

Customization and Flexibility

Modern control panels can be tailored to specific operational needs, whether it’s a complex manufacturing line or a marine vessel’s power distribution system.

For example, in a marine environment, a modern control panel can integrate navigation systems, engine controls, and safety alarms into a single interface. This integration streamlines operations and enhances situational awareness.

How to Choose the Right Modern Control Panel

Selecting the right control panel requires careful consideration of several factors:

Application Requirements

Define the specific functions the panel must perform. Consider the complexity of the machinery, the level of automation, and environmental conditions.

Compliance and Standards

Ensure the panel meets relevant industry standards such as UL, IEC, or ABS for marine applications.

Scalability

Choose a design that allows for future expansion or upgrades without complete replacement.

User Interface

Evaluate the ease of use and accessibility of the control panel’s interface. Training requirements should be minimal.

Supplier Support

Work with manufacturers or suppliers who offer technical support, customization options, and reliable after-sales service.

Budget and ROI

Balance upfront costs with long-term savings from improved efficiency, reduced downtime, and lower maintenance.

By following these guidelines, you can ensure that your investment in a modern control panel delivers maximum value.

Embracing the Future with Advanced Control Panels

The evolution of control technology continues at a rapid pace. Emerging trends such as IoT integration, cloud-based monitoring, and AI-driven analytics promise to further enhance the capabilities of control panels. Staying informed and adopting these innovations will keep your systems competitive and resilient.

For those interested in deeper technical details or specific product recommendations, I recommend exploring resources like control panels that provide comprehensive FAQs and expert insights.

Modern control panels are more than just electrical boxes - they are the nerve centers of today’s complex industrial and marine operations. Investing in the right technology today means safer, smarter, and more efficient systems tomorrow.