Designing Reliable and Efficient Control Panels: Mastering Control Panel Planning

- Ryan Patrick Murray

- Jan 21

- 4 min read

In industrial and marine environments, the backbone of operational success lies in the robustness of electrical control systems. Designing reliable and efficient control panels is not just a technical task; it is a strategic imperative. At Fail-Safe Electric, we understand that every control panel must deliver precision, safety, and durability under demanding conditions. This post dives deep into the essentials of control panel planning, offering practical insights to help you build systems that stand the test of time.

The Fundamentals of Control Panel Planning

Effective control panel planning begins with a clear understanding of the operational environment and the specific needs of the application. Whether it’s a marine vessel navigating rough seas or an industrial plant running complex machinery, the control panel must be tailored to meet those challenges.

Key considerations include:

Environmental Conditions: Moisture, temperature extremes, vibration, and corrosive atmospheres all influence material selection and enclosure design.

Safety Standards: Compliance with industry regulations such as UL, IEC, and NEC ensures the panel meets legal and safety requirements.

Component Selection: Choosing high-quality, compatible components reduces failure rates and simplifies maintenance.

Space Optimization: Efficient layout minimizes wiring complexity and improves airflow for cooling.

Future Expansion: Designing with scalability in mind allows for easy upgrades and modifications.

By addressing these factors early, you lay the groundwork for a control panel that performs reliably and efficiently.

Best Practices for Reliable and Efficient Control Panel Design

Reliability and efficiency are the twin pillars of successful control panels. Achieving both requires meticulous attention to detail and adherence to proven engineering principles.

Structured Wiring and Labeling

Organized wiring reduces troubleshooting time and prevents errors. Use color-coded wires and clear labels for each connection point. This practice not only enhances safety but also speeds up maintenance and future modifications.

Thermal Management

Heat is a silent enemy of electrical components. Incorporate ventilation, fans, or heat exchangers to maintain optimal temperatures. Position heat-generating devices away from sensitive electronics to prevent premature failure.

Redundancy and Fail-Safe Features

In critical applications, redundancy ensures continuous operation even if one component fails. Implement backup power supplies, dual controllers, or parallel circuits where necessary. Fail-safe mechanisms, such as emergency stop buttons and alarms, add an extra layer of protection.

Modular Design

Modularity simplifies assembly and repair. Use standardized modules that can be swapped out quickly without disturbing the entire system. This approach reduces downtime and lowers maintenance costs.

Documentation and Testing

Comprehensive documentation, including wiring diagrams, component datasheets, and test reports, is essential. Rigorous testing under simulated operating conditions verifies performance and uncovers potential issues before deployment.

By integrating these best practices, you create control panels that not only meet but exceed operational demands.

What are the latest trends in panel board design?

The landscape of control panel design is evolving rapidly, driven by advances in technology and changing industry needs. Staying current with these trends is crucial for maintaining competitive advantage.

Smart Panels with IoT Integration

Modern control panels increasingly incorporate Internet of Things (IoT) technology. Sensors and communication modules enable real-time monitoring, predictive maintenance, and remote diagnostics. This connectivity enhances operational efficiency and reduces unexpected downtime.

Compact and Lightweight Designs

Space constraints and weight limitations, especially in marine applications, push designers toward more compact panels. Advances in component miniaturization and innovative enclosure materials allow for smaller, lighter, yet equally robust solutions.

Enhanced Cybersecurity Measures

As control panels become more connected, cybersecurity becomes paramount. Incorporating secure communication protocols, firewalls, and access controls protects critical infrastructure from cyber threats.

Energy Efficiency and Sustainability

Energy-efficient components and power management strategies reduce operational costs and environmental impact. Designers are also adopting recyclable materials and eco-friendly manufacturing processes.

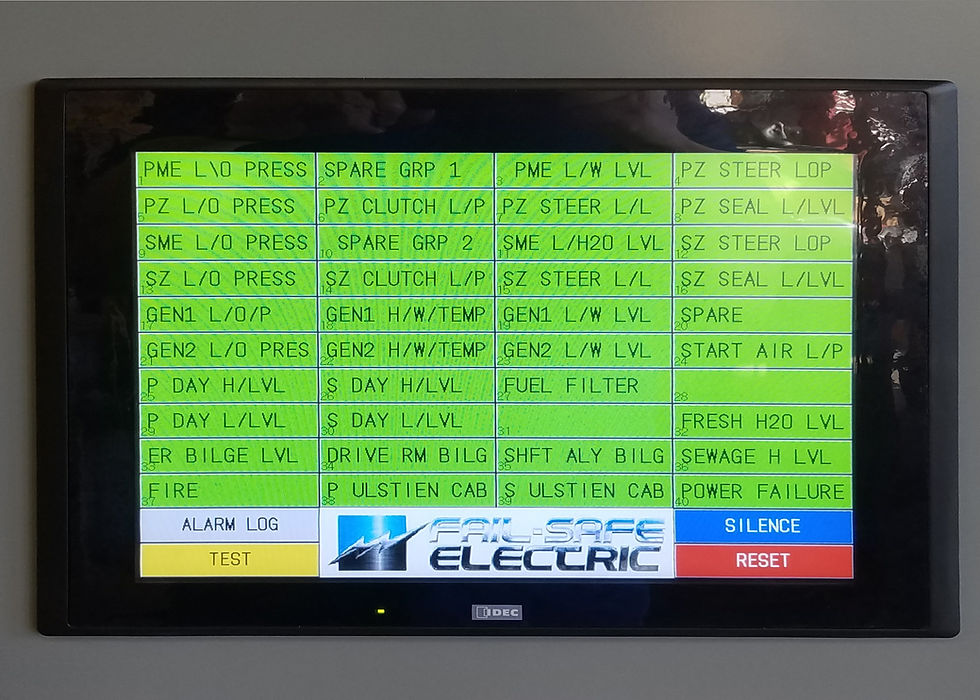

User-Friendly Interfaces

Touchscreens, graphical displays, and intuitive controls improve usability. Operators can interact with systems more effectively, reducing errors and training time.

Embracing these trends ensures your control panels remain at the forefront of technology and functionality.

Practical Steps to Implement Effective Control Panel Planning

Turning theory into practice requires a structured approach. Here are actionable steps to guide your control panel planning process:

Define Objectives Clearly: Identify the specific functions, performance criteria, and environmental conditions.

Conduct Risk Assessments: Evaluate potential hazards and failure modes to inform design choices.

Select Suitable Components: Prioritize reliability, compatibility, and compliance with standards.

Design the Layout: Use CAD tools to optimize space, wiring paths, and cooling.

Develop Detailed Documentation: Prepare schematics, wiring diagrams, and installation guides.

Prototype and Test: Build a prototype and conduct thorough testing under real-world conditions.

Train Personnel: Ensure operators and maintenance staff understand the system fully.

Plan for Maintenance: Establish schedules and procedures for regular inspections and updates.

Following these steps minimizes surprises and maximizes system uptime.

Why Choose Fail-Safe Electric for Your Control Panel Needs?

At Fail-Safe Electric, we specialize in custom control panel solutions tailored to the unique demands of industrial and marine environments. Our expertise ensures your systems are built with precision, safety, and efficiency at their core.

Customized Solutions: We design panels that fit your exact specifications and operational challenges.

Quality Assurance: Rigorous testing and quality control guarantee dependable performance.

Expert Support: Our team provides ongoing technical support and consultation.

Innovative Technologies: We integrate the latest advancements to future-proof your investment.

Commitment to Safety: Every panel meets or exceeds industry safety standards.

Partnering with Fail-Safe Electric means investing in control panels that deliver peace of mind and operational excellence.

Designing reliable and efficient control panels is a complex but rewarding endeavor. With careful control panel planning, adherence to best practices, and awareness of emerging trends, you can build systems that empower your operations to run smoothly and safely. For tailored solutions that meet the highest standards, trust Fail-Safe Electric to be your expert partner.

Explore more about our approach to control panel design and discover how we can help you achieve unmatched reliability and efficiency.