Exploring Different Types of Control Panels

- Ryan Patrick Murray

- Nov 10, 2025

- 4 min read

In the world of electrical engineering and industrial applications, understanding the various types of control panels is essential. These panels serve as the nerve centers for managing electrical systems, ensuring safety, efficiency, and reliability. Whether you are overseeing a marine vessel’s electrical setup or managing an industrial facility, knowing the right control panel for your needs can make all the difference.

Understanding the Types of Control Panels

Control panels come in many forms, each designed to meet specific operational requirements. The choice depends on factors such as the complexity of the system, environmental conditions, and the level of automation required. Here are some of the most common types:

Motor Control Panels (MCPs)

These panels are designed to control electric motors. They include components like motor starters, overload relays, and circuit breakers. MCPs are widely used in manufacturing plants and marine propulsion systems where precise motor control is critical.

Distribution Control Panels (DCPs)

DCPs distribute electrical power to various circuits and equipment. They typically contain circuit breakers, fuses, and busbars. These panels ensure that power is safely and efficiently routed to different parts of a facility or vessel.

Programmable Logic Controller (PLC) Panels

PLC panels house programmable controllers that automate complex processes. They are essential in industries requiring precise control and monitoring, such as chemical processing or automated manufacturing lines.

Instrumentation Control Panels

These panels focus on monitoring and controlling instrumentation devices like sensors and meters. They provide real-time data and control signals, crucial for maintaining system performance and safety.

Fire Alarm Control Panels

Specialized for safety, these panels manage fire detection and alarm systems. They integrate with sensors and notification devices to provide early warnings and system status.

Each type serves a unique purpose but shares the common goal of centralizing control and enhancing system reliability.

What is the control panel?

At its core, a control panel is an assembly of electrical components housed within an enclosure. It acts as the interface between the operator and the machinery or system it controls. The panel organizes and protects devices such as switches, relays, circuit breakers, and controllers.

Control panels simplify complex electrical systems by consolidating control functions into a single, accessible location. This consolidation improves safety by reducing wiring complexity and providing clear access points for maintenance and troubleshooting.

For example, in a marine environment, a control panel might manage everything from engine start-up sequences to lighting and navigation systems. In an industrial setting, it could coordinate conveyor belts, robotic arms, and safety interlocks.

The design of a control panel must consider environmental factors like moisture, dust, and temperature. Panels intended for harsh environments often feature rugged enclosures with specific ratings such as NEMA or IP standards to ensure durability.

Key Components Inside Control Panels

Understanding the internal components helps in selecting or designing the right panel. Here are the critical elements you will find inside most control panels:

Circuit Breakers and Fuses: Protect circuits from overloads and short circuits.

Relays and Contactors: Electrically operated switches that control power flow.

Transformers: Step voltage levels up or down to suit different devices.

Programmable Logic Controllers (PLCs): Provide automation and logic control.

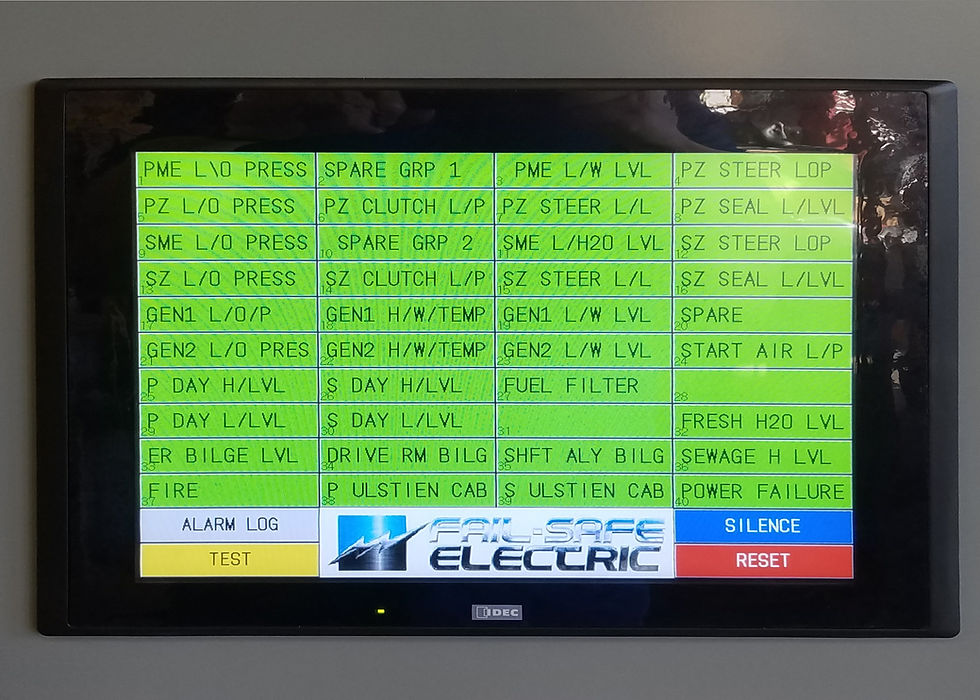

Human-Machine Interface (HMI): Displays system status and allows operator input.

Terminal Blocks: Connect wiring securely and neatly.

Power Supplies: Convert and regulate electrical power for panel components.

Each component plays a vital role in ensuring the panel operates safely and efficiently. Proper selection and integration of these parts are crucial for system performance.

Selecting the Right Control Panel for Your Application

Choosing the appropriate control panel requires a clear understanding of your system’s needs. Here are some practical steps to guide your decision:

Assess System Complexity

Simple systems may only need basic motor control panels, while complex processes might require PLC panels with advanced automation.

Consider Environmental Conditions

Panels exposed to moisture, dust, or extreme temperatures need enclosures rated for those conditions.

Evaluate Safety Requirements

Fire alarm panels or emergency shutdown systems must comply with strict safety standards.

Plan for Future Expansion

Select panels with room for additional components or upgrades to avoid costly replacements.

Consult Industry Standards

Adhering to standards such as UL, IEC, or NEMA ensures compliance and reliability.

Work with Experienced Manufacturers

Partnering with reputable suppliers guarantees quality components and expert support.

By following these guidelines, you can ensure your control panel will meet operational demands and provide long-term value.

Maintenance and Troubleshooting Tips

Proper maintenance extends the life of control panels and prevents costly downtime. Here are some actionable recommendations:

Regular Inspections: Check for loose connections, corrosion, and signs of wear.

Clean Enclosures: Remove dust and debris to prevent overheating.

Test Protective Devices: Verify circuit breakers and relays function correctly.

Update Software: Keep PLC and HMI firmware current to avoid bugs.

Document Changes: Maintain accurate records of modifications and repairs.

Train Personnel: Ensure operators and technicians understand panel operation and safety protocols.

When troubleshooting, start with visual inspections and move to electrical testing. Use diagnostic tools like multimeters and thermal cameras to identify issues quickly.

Embracing Modern Control Panel Technologies

The evolution of control panels continues with advances in digital technology and connectivity. Modern panels often feature:

Remote Monitoring: Access system status and control functions from anywhere.

IoT Integration: Connect panels to the Internet of Things for data analytics and predictive maintenance.

Energy Efficiency: Incorporate energy-saving components and smart controls.

Modular Designs: Allow easy upgrades and customization.

Enhanced Safety Features: Include advanced fault detection and emergency shutdown capabilities.

Adopting these technologies can improve operational efficiency, reduce costs, and enhance safety.

For more detailed information on control panels, including specifications and FAQs, visiting specialized resources is highly recommended.

Final Thoughts on Control Panel Selection and Use

Choosing and managing the right control panel is a critical task that impacts system performance and safety. By understanding the different types, components, and maintenance practices, you can make informed decisions that support your operational goals.

Remember, a well-designed control panel is more than just a collection of parts - it is the command center that keeps your electrical systems running smoothly and reliably. Invest the time and resources to get it right, and the benefits will follow.